Unlocking Precision and Creativity with Embroidery Digitizing Services

In today’s design-focused market, businesses and creators are looking for new ways to improve brand identity and deliver meaningful experiences to their audiences. Custom embroidery remains a reliable method for adding quality, personality, and professionalism to apparel, accessories, and promotional materials. Yet the real foundation of modern embroidery begins with embroidery digitizing services.

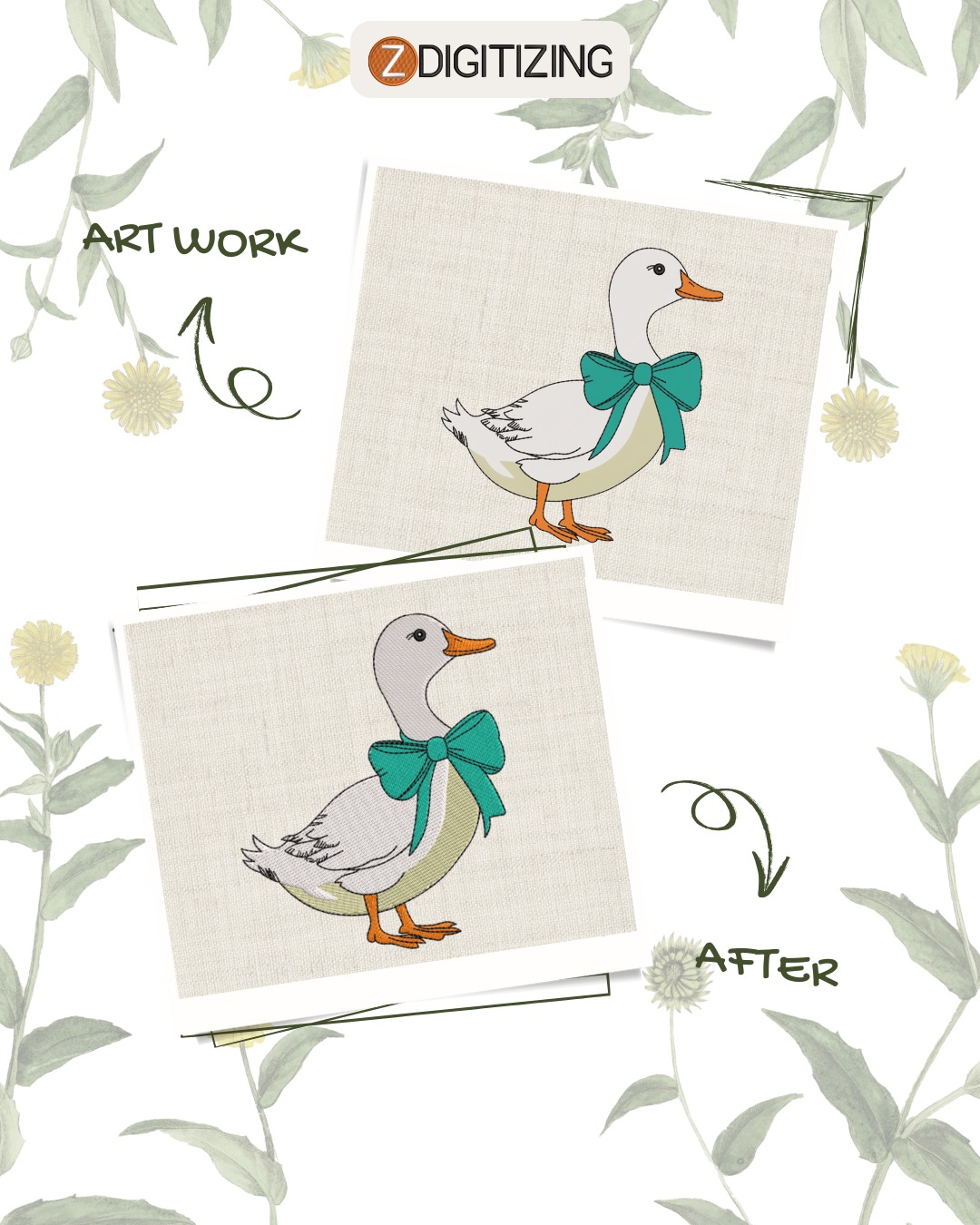

Embroidery digitizing is the process of converting artwork, logos, and detailed illustrations into a stitch file that embroidery machines can understand. This file guides the machine in placing every stitch with accuracy. As personalization in fashion continues to rise and automated production becomes more common, the demand for reliable digitizing services has increased significantly.

Why Embroidery Digitizing Is Essential

Many people assume an embroidery machine can work from a standard digital image, but machines interpret only stitches. They require a properly prepared stitch file that takes fabric type, stitch density, and design complexity into account.

A professionally digitized design support:

- Clean stitching with sharp detail

- Correct thread density

- Reliable registration and alignment

- Reduced thread breaks

- Faster production times

- Long-lasting embroidered results

Without expert digitizing, even high-quality equipment can produce uneven or distorted embroidery. This is why digitizing services have become a critical resource for embroidery shops, printing companies, promotional product suppliers, fashion labels, and small businesses offering personalized items.

Key Benefits of Professional Digitizing Services

Outsourcing digitizing offers several practical advantages for both new and established businesses.

1. Greater Design Accuracy

Experienced digitizers understand how different stitch types interact with various fabrics. This ensures that logos, small lettering, gradients, and complex images maintain clarity once stitched.

2. Faster Project Completion

Instead of spending time learning digitizing software or fixing stitch issues, businesses can receive ready-to-use files quickly. This helps reduce production delays and improve workflow efficiency.

3. Improved Fabric Compatibility

Every fabric behaves differently. Stretchy materials, thick garments, and textured surfaces all require unique digitizing methods. A skilled digitizer adjusts stitch patterns and underlay techniques to prevent puckering, distortion, or excessive density.

4. Cost-Effective Production

Digitizing software and training can be expensive. Outsourcing helps businesses save money while maintaining dependable quality, especially when dealing with frequent or complex custom orders.

5. Reliable Scalability

Whether the need is for a single small design or a large batch of corporate logos, digitizing services scale easily. This is particularly helpful for busy seasons, event-related orders, or long-term branding projects.

Common Types of Embroidery Digitizing

Digitizing must be tailored to the final use of the design. Some of the most common types include:

- Logo Digitizing for company apparel and branded items

- 3D Puff Digitizing for raised embroidery on structured garments

- Appliqué Digitizing for designs that incorporate fabric pieces

- Monogram Digitizing for personalized fashion and accessories

- Patch Digitizing for badges and emblems

Each category requires specific stitch strategies, which is why experienced digitizers remain important in the embroidery industry.

Qualities of a High-Quality Digitized Design

A strong digitized file improves both visual appeal and durability. Important elements include:

- Balanced stitch density

- Proper underlay to stabilize the fabric

- Logical pathing to reduce unnecessary trims

- Legible small lettering

- Accurate edge control

- Suitable use of stitch types such as satin, fill, and run

- Organized color mapping

When these elements are applied correctly, the final embroidered work maintains clarity and structure throughout production.

Industries That Depend on Digitizing Services

A wide range of industries use embroidery digitizing, such as:

- Fashion and streetwear brands

- Promotional product companies

- Sports teams and athletic apparel manufacturers

- Small businesses offering personalized gifts

- E-commerce shops selling custom items

- Home-based embroidery creators

With customization becoming a strong trend in product design, digitizing services support both large-scale production and individual creative projects.

The Future of Embroidery Digitizing

The digitizing field continues to grow with improvements in automation, AI-assisted software, and advanced embroidery equipment. These innovations help create cleaner, more detailed designs with less manual editing. As demand increases for personalized products, sustainable production methods, and short-run manufacturing, skilled digitizing will remain an essential part of the embroidery process.

Conclusion

Embroidery digitizing services form the technical foundation that makes high-quality embroidery possible. They bridge the gap between creative artwork and machine production, helping businesses achieve consistent, professional results.

Whether you run an embroidery shop, operate an apparel brand, or design custom products, strong digitizing supports better efficiency, reliable stitching, and dependable quality. If your goal is precise and well-crafted embroidery, expert digitizing is a key step in transforming your design into a finished product that customers appreciate.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness