Additive Manufacturing with Metal Powders Market Graph: Growth, Share, Value, Size, and Insights By 2029

Future of Executive Summary Additive Manufacturing with Metal Powders Market: Size and Share Dynamics

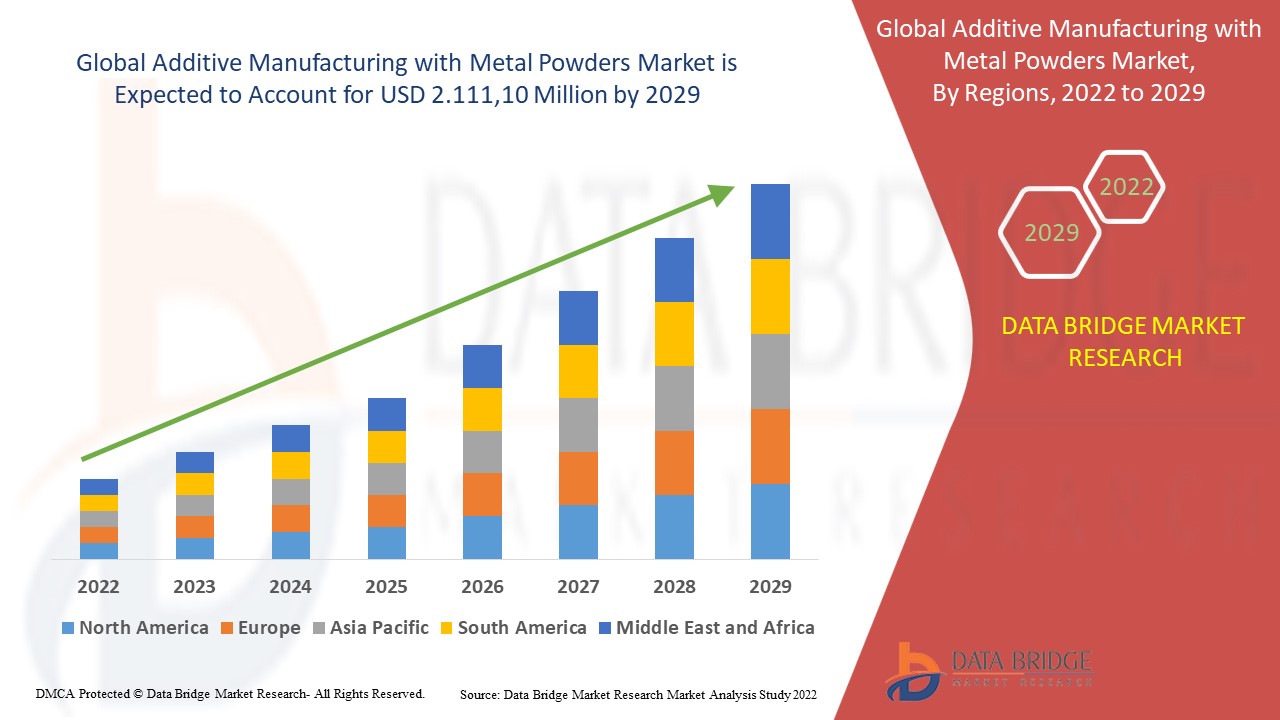

Data Bridge Market Research analyses that the additive manufacturing with metal powders market will witness a CAGR of 22.1% for the forecast period of 2022-2029 and is likely to reach at USD 2.111,10 million by 2029.

Businesses can attain detailed insights with the large scale Additive Manufacturing with Metal Powders survey report which help them self-assuredly make decisions about their production and strategies in Additive Manufacturing with Metal Powders industry. The report describes various parameters throughout which analyses the status in detail. It also endows with statistics on the current state of the industry and hence works as a valuable source of guidance and direction for companies and investors interested in this market. The whole Additive Manufacturing with Metal Powders report can be mainly categorised into four main areas which are definition, segmentation, competitive analysis and research methodology.

To have finest insights and knowhow of the most excellent opportunities into the specific markets, Additive Manufacturing with Metal Powders research report is an ideal option. The report carries out the study of the with respect to general conditions, status, improvement, key developments, cost and profit of the specified regions, position and comparative pricing between major players. Each topic of this report is examined very wisely to acquire a clear idea about all the factors that are influencing the growth and Additive Manufacturing with Metal Powders industry. The research study that has taken place in the large-scale Additive Manufacturing with Metal Powders report covers the local, regional as well as global market.

Tap into future trends and opportunities shaping the Additive Manufacturing with Metal Powders Market. Download the complete report:

https://www.databridgemarketresearch.com/reports/global-additive-manufacturing-with-metal-powders-market

Additive Manufacturing with Metal Powders Environment

Segments

- Type: The global additive manufacturing with metal powders can be segmented by type into Selective Laser Melting (SLM), Electron Beam Melting (EBM), Direct Metal Laser Sintering (DMLS), Powder Bed Fusion, and Others.

- Metal Type: Based on the metal type, the can be segmented into Titanium, Nickel, Stainless Steel, Aluminum, Cobalt Chrome, and Others.

- End-Use Industry: The end-use industry segment includes Aerospace & Defense, Automotive, Healthcare, Oil & Gas, and Others.

Players

- EOS GmbH Electrol Optical Systems

- Concept Laser

- SLM Solutions

- 3D Systems, Inc.

- Arcam AB

- Renishaw plc

- ExOne

- Materialise

- Markforged

- GE Additive

- Voxeljet

The global additive manufacturing with metal powders is witnessing significant growth due to the increasing adoption of metal additive manufacturing across various industries. The technology offers benefits such as design flexibility, reduced waste, faster production cycles, and enhanced product performance. The aerospace and defense sector, in particular, is a key driver for the as manufacturers in this industry increasingly rely on additive manufacturing for complex parts production.

Selective Laser Melting (SLM) and Electron Beam Melting (EBM) are among the most widely used technologies in the market, offering high precision and superior quality in metal parts production. Titanium and stainless steel are the dominant metal types being used in additive manufacturing with metal powders, driven by their excellent mechanical properties and corrosion resistance.

The healthcare industry is also a significant contributor to the growth, with applications in orthopedic implants, dental prosthetics, and medical instruments. The ability of metal additive manufacturing to create customized and patient-specific medical devices is fueling its adoption in the healthcare sector.

Key players such as EOS GmbH Electrol Optical Systems, Concept Laser, and SLM Solutions are focused on developing advanced metal additive manufacturing technologies to meet the growing demand from various industries. Partnerships, collaborations, and acquisitions are common strategies employed by these players to expand their presence and enhance their product offerings.

Overall, the global additive manufacturing with metal powders is poised for continued expansion, driven by technological advancements, increasing investment in research and development, and the growing adoption of additive manufacturing across diverse industries.

https://The global additive manufacturing with metal powders is experiencing a transformational phase driven by advancements in technology and a shift towards more sustainable and efficient manufacturing processes. One key trend shaping the is the increasing focus on multi-material additive manufacturing. This approach allows for the integration of different metals within a single part, enabling enhanced functionalities and improved performance characteristics. Industries such as aerospace, automotive, and healthcare are leveraging this capability to create complex components with unique material properties tailored to specific application requirements.

Another significant trend in the is the rise of hybrid additive manufacturing solutions. These systems combine traditional subtractive manufacturing techniques with additive processes to offer a more versatile and cost-effective approach to production. By integrating laser-based powder bed fusion technology with machining capabilities, manufacturers can achieve higher precision, better surface finish, and increased productivity, catering to a wider range of applications across diverse industries.

Moreover, the emphasis on sustainability and environmental responsibility is driving the adoption of additive manufacturing with metal powders. By reducing material waste, energy consumption, and overall production footprint, this technology aligns with the growing demand for eco-friendly manufacturing practices. As regulatory pressure and consumer preferences push for greener solutions, additive manufacturing offers a compelling value proposition for businesses looking to minimize their environmental impact while maintaining operational efficiency.

Furthermore, the is witnessing a surge in demand for on-demand and decentralized manufacturing models enabled by additive manufacturing with metal powders. This shift towards distributed production networks allows companies to respond quickly to changing demands, reduce lead times, and optimize supply chain agility. By leveraging digital design tools, cloud-based platforms, and additive manufacturing capabilities, organizations can establish more resilient and cost-effective manufacturing ecosystems that enhance competitiveness and customer satisfaction.

In conclusion, the global additive manufacturing with metal powders is poised for substantial growth driven by technological innovation, evolving industry requirements, and a focus on sustainability and efficiency. As players continue to invest in research and development, collaborate on new solutions, and expand their product portfolios, the landscape of additive manufacturing with metal powders will evolve to meet the diverse needs of modern manufacturing environments. By embracing emerging trends and leveraging the inherent benefits of additive manufacturing, businesses can unlock new opportunities for growth, differentiation, and overall success in an increasingly competitive market.The global additive manufacturing with metal powders is a dynamic and rapidly evolving sector that is driven by a combination of technological advancements, industry-specific applications, and key players. One of the major trends shaping the is the increasing adoption of metal additive manufacturing across a wide range of industries, including aerospace, automotive, healthcare, and oil & gas. This trend is fueled by the numerous benefits offered by additive manufacturing, such as design flexibility, reduced waste, faster production cycles, and enhanced product performance.

In terms of metal type segmentation, titanium and stainless steel are leading the due to their excellent mechanical properties and corrosion resistance. These metals are widely used in additive manufacturing processes to create high-quality and durable components for various applications. Additionally, the aerospace and defense industry stands out as a significant driver of growth, where additive manufacturing technologies such as Selective Laser Melting (SLM) and Electron Beam Melting (EBM) are extensively utilized for producing complex and lightweight parts.

Furthermore, the healthcare sector is emerging as a key contributor to the expansion, leveraging metal additive manufacturing for orthopedic implants, dental prosthetics, and customized medical devices. The ability to create patient-specific implants and devices through additive manufacturing is revolutionizing the healthcare industry, offering personalized solutions that optimize patient outcomes and treatment efficacy.

Key players such as EOS GmbH Electrol Optical Systems, Concept Laser, and SLM Solutions are at the forefront of driving innovation in metal additive manufacturing technologies. These companies are actively investing in research and development to bring advanced solutions to the and cater to the evolving needs of various industries. Collaborations, partnerships, and acquisitions are common strategies adopted by players to strengthen their presence and deliver cutting-edge additive manufacturing solutions to their customers.

Overall, with the rise of trends such as multi-material additive manufacturing, hybrid additive manufacturing solutions, and a focus on sustainability, the global additive manufacturing with metal powders is poised for significant growth and transformation. As industry demands continue to evolve and technology advancements accelerate, the landscape is expected to witness further developments, presenting new opportunities for players to innovate, collaborate, and drive the adoption of metal additive manufacturing across diverse sectors.

Evaluate the company’s influence on the market

https://www.databridgemarketresearch.com/reports/global-additive-manufacturing-with-metal-powders-market/companies

Forecast, Segmentation & Competitive Analysis Questions for Additive Manufacturing with Metal Powders Market

- What is the estimated revenue size for the Additive Manufacturing with Metal Powders Market?

- How fast is the Additive Manufacturing with Metal Powders evolving?

- What are the emerging segments in this market?

- Who are the global influencers in the Additive Manufacturing with Metal Powders Market?

- What are the breakthroughs in product development?

- What is the regional diversity in the Additive Manufacturing with Metal Powders study?

- Which region is most attractive for new entrants?

- What countries are posting consistent growth?

- What markets are nearing saturation?

- What consumer behaviors are shaping future trends?

Browse More Reports:

Global Laser Land Levelers Market

Global Laser Printer Market

Global Laurence Moon Biedl Syndrome Market

Global Liquid Crystal Display (LCD) Digital Signage Market

Global Low Density Polyethylene (LDPE) and Linear Low-Density Polyethylene (LLDPE) Sealant Web Film Market

Global Leather Luggage and Goods Market

Global Lectins (Carbohydrate Binding Proteins) Market

Global Left Ventricular Assist Device (LVAD) Market

Global Leukapheresis Market

Global Light Attack and Reconnaissance Aircraft Market

Global Limestone for Agriculture Market

Global Lithium Chloride Market

Global Liver Fibrosis Drugs Market

Global Livestock Grow Lights Market

Global Long Chain Dicarboxylic Acid (LCDA) Acid Market

About Data Bridge Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Research set forth itself as an unconventional and neoteric research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness