What Innovations Are Powering the Factory Automation Market?

"Executive Summary Factory Automation Market Size and Share Across Top Segments

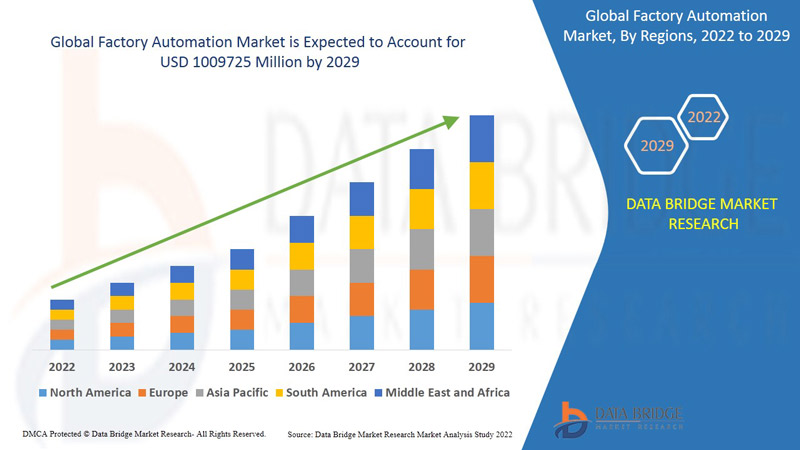

Data Bridge Market Research analyses the market to rise up to the USD 1009725 million by 2029 and to grow at a CAGR of 9.60% in the above-mentioned forecast period.

Factory Automation Market is a detailed market research report that serves many purposes and gives the business a competitive advantage. To stand apart from the competition, a careful idea about the competitive landscape, their product range, their strategies, and future prospects is very important. This market report endows with CAGR value fluctuations during the forecast period of 2022-2029 for the market. Furthermore, systemic company profiles covered in the large scale Factory Automation Market report also explains what recent developments, product launches, joint ventures, mergers and acquisitions are taking place by the numerous key players and brands in the market.

The analysis and estimations carried out via a wide ranging Factory Automation Market document help to obtain an idea about the product launches, future products, joint ventures, marketing strategy, developments, merges and accusations and effect of the same on sales, marketing, promotions, revenue, import, export, and CAGR values. The report helps in determining and optimizing each stage in the lifecycle of industrial process that includes engagement, acquisition, retention, and monetization. An excellent Factory Automation Market report presents with the numerous insights and business solutions that will help to stay ahead of the competition.

Review comprehensive data and projections in our Factory Automation Market report. Download now:

https://www.databridgemarketresearch.com/reports/global-factory-automation-market

Factory Automation Market Growth Snapshot

Segments

- Based on product type, the global factory automation market can be segmented into Programmable Logic Controller (PLC), Industrial PC, Human Machine Interface (HMI), SCADA, Machine Vision, and others. PLCs are widely used in factory automation for controlling manufacturing processes. Industrial PCs are essential for data acquisition and control applications. HMI systems provide the interface for operators to monitor and manage machines. SCADA systems enable real-time monitoring of industrial processes. Machine vision systems are used for quality control and inspection tasks.

- By end-user industry, the market can be classified into automotive, food and beverage, pharmaceuticals, chemicals, oil and gas, electronics, and others. The automotive industry is a significant adopter of factory automation technologies for improving production efficiency and quality control. The food and beverage sector utilizes automation for packaging and processing operations. Pharmaceuticals require automation for precise and compliant manufacturing processes. The chemicals industry benefits from automation for handling hazardous materials safely. Oil and gas companies deploy automation for drilling, production, and refining activities. Electronics manufacturing relies heavily on automation for high-precision assembly processes.

- On the basis of region, the global factory automation market is segmented into North America, Europe, Asia Pacific, and the rest of the world. Asia Pacific is a key region for factory automation due to the presence of major manufacturing hubs like China, Japan, and South Korea. North America and Europe also have mature factory automation markets driven by technological advancements and adoption in various industries.

Market Players

- Some of the prominent players in the global factory automation market include Siemens AG, ABB Ltd, Rockwell Automation Inc, Schneider Electric SE, Mitsubishi Electric Corporation, Omron Corporation, Yokogawa Electric Corporation, Emerson Electric Co, Honeywell International Inc, and General Electric Company. These companies offer a wide range of automation solutions such as controllers, sensors, actuators, software, and services to cater to the diverse needs of industrial clients. They focus on innovation, product development, strategic partnerships, and acquisitions to enhance their market presence and offer cutting-edge solutions to customers.

The global factory automation market is witnessing significant growth driven by various factors such as increasing demand for process optimization, enhanced production efficiency, and the need for cost reduction in manufacturing operations. One key trend emerging in the market is the integration of advanced technologies like artificial intelligence, Internet of Things (IoT), and cloud computing to enable smart factory concepts and Industry 4.0 initiatives. These technologies are revolutionizing the manufacturing landscape by enabling real-time monitoring, predictive maintenance, and seamless connectivity across the production line.

Moreover, the adoption of collaborative robots, also known as cobots, is gaining traction in the factory automation sector. These robots are designed to work alongside human operators, enhancing productivity, flexibility, and safety in manufacturing environments. The versatility of cobots makes them suitable for a wide range of applications, from material handling and assembly to quality inspection and packaging. As companies focus on creating agile and adaptable production processes, cobots are becoming integral components of modern factory automation systems.

In terms of market dynamics, the global factory automation industry is facing challenges related to cybersecurity threats and data privacy concerns. With the increasing connectivity of machines and devices in industrial settings, there is a growing risk of cyberattacks that could disrupt operations and compromise sensitive information. As a result, manufacturers are investing in robust cybersecurity measures and proactive risk management strategies to safeguard their automation systems and data.

Furthermore, the demand for customized automation solutions tailored to specific industry requirements is on the rise. Manufacturers across various sectors are seeking flexible and scalable automation technologies that can be easily integrated into existing production setups. This trend is driving innovation in the market, prompting automation providers to develop modular and customizable solutions that can adapt to changing production needs and business environments.

Looking ahead, the global factory automation market is poised for continued growth as industries worldwide embrace digital transformation and automation technologies to stay competitive in a rapidly evolving market landscape. The convergence of traditional manufacturing practices with cutting-edge automation solutions is shaping the future of industrial production, offering opportunities for market players to innovate, collaborate, and drive sustainable growth in the industry.The global factory automation market is undergoing a profound transformation driven by the integration of advanced technologies and the adoption of smart manufacturing concepts. The shift towards Industry 4.0 initiatives is reshaping traditional production processes, leading to increased efficiency, agility, and competitiveness in the industrial sector. The implementation of artificial intelligence, Internet of Things (IoT), and cloud computing is enabling real-time data analytics, predictive maintenance, and seamless connectivity across the factory floor. These technologies are revolutionizing the way manufacturers operate, allowing them to optimize processes, reduce downtime, and enhance overall productivity.

One of the key trends in the market is the rising uptake of collaborative robots, or cobots, in factory automation systems. These robots are designed to work alongside human operators, augmenting workforce capabilities and improving operational flexibility. Cobots are particularly well-suited for tasks that require close human-robot interaction, such as assembly, material handling, and inspection. Their ease of programming, safety features, and adaptability make them valuable assets in dynamic manufacturing environments. As companies seek to streamline operations and enhance production efficiency, the integration of cobots is becoming increasingly prevalent across various industries.

Cybersecurity remains a critical concern for the factory automation industry, given the proliferation of interconnected devices and systems in industrial environments. The growing threat of cyberattacks poses significant risks to operational continuity and data integrity, prompting manufacturers to prioritize cybersecurity measures and risk mitigation strategies. Ensuring the resilience of automation systems against potential threats is crucial to maintaining a secure and reliable production infrastructure. As digitalization accelerates and connectivity expands, safeguarding sensitive information and critical assets from cyber vulnerabilities becomes paramount for industry stakeholders.

Besides, the demand for customized automation solutions tailored to specific industry requirements is driving innovation and market growth. Manufacturers are seeking adaptive and scalable automation technologies that can cater to evolving production needs and operational challenges. Automation providers are responding to this demand by offering modular, flexible solutions that can be easily integrated into existing workflows and customized to meet diverse industry applications. The ability to deliver tailored automation solutions that align with customer expectations and operational objectives is becoming a key differentiator for market players seeking to stay competitive in a rapidly evolving industrial landscape.

In conclusion, the global factory automation market is poised for sustained expansion as businesses embrace digital transformation and innovative technologies to drive operational excellence and sustainable growth. The convergence of advanced automation solutions with traditional manufacturing practices is creating new opportunities for industry players to collaborate, innovate, and deliver value-added services to customers. As the market continues to evolve, strategic investments in technological advancements, cybersecurity resilience, and customized automation offerings will be critical for unlocking the full potential of smart manufacturing and Industry 4.0 initiatives across various sectors.

Get a closer look at the company’s market penetration

https://www.databridgemarketresearch.com/reports/global-factory-automation-market/companies

Global Factory Automation Market – Segmentation & Forecast Question Templates

- What is the current valuation of the Factory Automation Market?

- How has the Factory Automation Market grown in the past 5 years?

- What are the major categories included in the Factory Automation Market?

- Who are the top-performing companies in this sector?

- What share of the Factory Automation Market do top 5 companies hold?

- Which countries are key contributors to market revenue?

- What technological trends are emerging in the market?

- What is the forecast period in the Factory Automation Market report?

- How are macroeconomic trends affecting the Factory Automation Market?

- What are the risks involved for new entrants?

- What investment opportunities exist in this Factory Automation Market?

- Which end-users dominate the Factory Automation Market?

- How competitive is the market landscape?

- What mergers and acquisitions have shaped the Factory Automation Market recently?

Browse More Reports:

Global Cattle Disinfectants Market

Global Chronic Bronchitis Market

Global Clinical Workflow Solutions Market

Global Coloboma, Heart Defects, Atresia Choanae, Growth Retardation, Genital Abnormalities, and Ear Abnormalities (CHARGE) Syndrome Treatment Market

Global Coordinate Measuring Machine Market

Global Crystalline Ceramic Fibers Market

Global Dark Spirit Market

Global Database Encryption Market

Global Diagnostic Systems Market

Global Disposable Lead Wires Market

Global Doctor Blade Market

Global Dome Security Market

Global Energy Based Therapeutics Market

Global Energy Efficient Warehouse Lighting System Market

Global Exanthema Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com

"

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness