Polycaprolactone Polyol Market Report 2024-2032 |

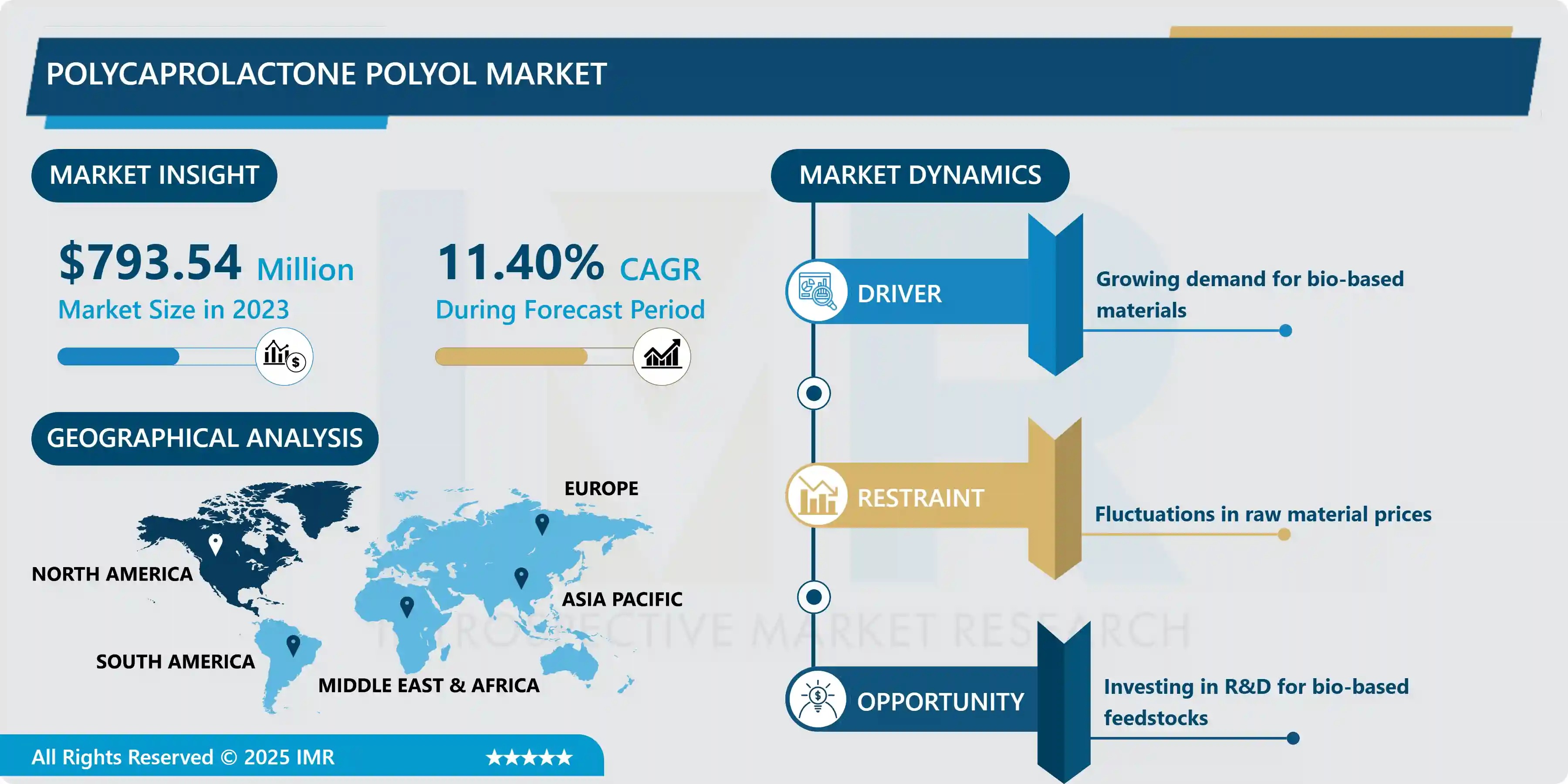

Introspective Market Research today released its in-depth Polycaprolactone (PCL) Polyol Market Report (2024–2032), forecasting growth from a base of USD 793.54 million in 2023 to USD 2,335.71 million by 2032, at a compound annual growth rate (CAGR) of 11.40%. This rapid acceleration is underpinned by growing demand for bio-based, biodegradable materials; tighter environmental regulations; and increasing use in high-performance applications like automotive coating elastomers, flexible foams, and medical-grade polyurethanes.

Quick Insights

- 2023 Market Size: USD 793.54 million

- 2032 Forecast: USD 2,335.71 million

- Projected CAGR (2024–2032): 11.40%

- Top Form: Liquid PCL polyols (as opposed to paste/wax)

- Leading Applications: Coating elastomer, adhesives, foam, and others

- Major End-Use Industries: Automotive, Printing, Footwear, Pharmaceuticals, ResinKey Players: BASF SE, Daicel Corporation, Perstorp, Alfa Aesar, Chongqing Huafeng Chemical Co.

What’s Driving the Polycaprolactone Polyol Market?

A push toward sustainable and biodegradable materials is at the heart of market growth. Polycaprolactone polyols offer excellent mechanical strength, flexibility, and environmental compatibility — making them highly attractive for green polyurethane production. At the same time, automotive, footwear, and construction sectors are increasingly adopting PCL-polyol-based coatings and elastomers for performance and regulatory compliance. Innovation in production techniques, such as more efficient polymerization and eco-friendly feedstocks, is also reducing costs and unlocking new applications.

What Opportunities & Trends Are Emerging?

Could PCL-polyol become the polymer of choice for next-gen green coatings and foams?

- Rising environmental regulations are driving demand for bio-based polyols — PCL offers a strong alternative over petrochemical-based polyols.

- Manufacturers are developing low-viscosity liquid PCL polyols to optimize processing in coatings and elastomer applications.

- Growth in electric vehicles and lightweight automotive design is creating demand for durable, flexible, and green polyurethanes.

- In biomedicine, PCL-polyol is playing an increasing role in implantable devices and resorbable scaffolds, supporting the circular economy.

Expert Commentary

“Polycaprolactone polyol is emerging as a sustainable backbone for high-performance polyurethane products,” said Dr. Meera Joshi, Principal Consultant at Introspective Market Research. “Its biodegradability, flexibility, and compatibility with eco-friendly chemistry make it uniquely suited for the future of materials innovation. Companies that scale PCL-polyol production and target applications like coatings, foam, and medical devices will lead the green transformation in polymer chemistry.”

Regional & Segment Analysis

- North America: Significant demand due to advanced automotive and specialty coating industries, coupled with strong environmental legislation pushing for greener polymers.

- Europe: Fast uptake driven by sustainability-focused policies, expanding construction sector, and eco-material frameworks.

- Asia-Pacific: Expected to witness the fastest growth due to rapid industrialization, rising automotive production, and strong demand in footwear and electronics.

By Application:

- Coating Elastomer: The largest application segment, thanks to PCL’s flexibility, UV resistance, and long-term durability.

- Adhesives: Demand is rising, particularly low-VOC PCL-based adhesives for sustainable construction and automotive use.

- Foam: Used in footwear, automotive interiors, and specialty polyurethane products where tensile strength and compression properties matter.

- Others: Include biomedical matrices, sealants, and specialty elastomers.

By End-User:

- Automotive: PCL-polyol is preferred in coatings, lightweight components, and durable elastomers.

- Pharmaceutical / Medical: Used in biomedical polyurethanes for implants and scaffolds due to its biodegradability.

- Footwear & Printing: Flexible foams and specialty resins benefit from PCL’s strength and elasticity.

Innovation & Breakthroughs

- Major players like BASF SE and Daicel Corporation are investing in scalable PCL-polyol production to meet growing demand.

- Research initiatives are focused on cross-linked PCL polyols to improve mechanical properties for high-performance foams and elastomers.

- Development of eco-sourced monomers and bio-catalysts is helping reduce the environmental footprint of PCL production.

- Tailored PCL-polyol chemistries for biomedical applications are being explored for controlled degradation and biocompatibility.

Challenges & Cost Pressures

- Raw Material Volatility: Fluctuations in the cost of caprolactone and monomers can pressure margin.

- Production Complexity: Synthesizing high-quality PCL-polyol requires precise control over molecular weights and polymer architecture.

- High Initial Investment: Ramping up production capacity for biodegradable polyols demands capital-intensive infrastructure.

- Competing Materials: Traditional polyols remain cheaper and well-established, especially in cost-sensitive markets.

- Regulatory Risks: Biodegradation claims and eco-labeling require rigorous testing and certification.

Benefit

- Sustainability: Biodegradable PCL-polyol supports circular economy goals and helps reduce reliance on petrochemicals.

- Performance: Flexibility, low viscosity, and high mechanical strength make PCL-polyol ideal for premium coatings, elastomers, and foams.

- Health & Safety: Potential for safer, low-emission formulations in automotive and construction applications.

- Innovation-Friendly: PCL-polyol’s versatility enables advanced applications in biomedical fields like implantable devices and drug-delivery systems.

Case Study (Illustrative)

A leading polyurethane manufacturer switched from conventional polyol to PCL-based polyol for its eco-conscious automotive coating line. Over 12 months:

- It reduced VOC (volatile organic compound) emissions by 25%, aligning with stricter environmental standards.

- The PCL formulation improved coating flexibility and durability, lowering warranty-related recalls by 15%.

- The company saw a 10% uplift in customer preference for its “green” line, boosting brand loyalty and revenue.

To access detailed forecasts, trend analysis, and company strategies, download a free sample of our Polycaprolactone Polyol Market Report (2024–2032) or schedule a one-on-one consultation with our chemical-specialist team.

🔗 Download Sample / Request Demo

About Introspective Market Research

Introspective Market Research is a leading intelligence firm specializing in advanced materials, sustainability markets, and chemical innovation. We deliver data-driven insights, forward-looking forecasts, and strategic advice to help companies navigate the rapidly evolving landscape of green chemistry.

Media Contact:

Arjun Mehta

Senior Communications Manager

Introspective Market Research

Email: media@introspectivemarketresearch.com

Phone: +91-91753-37569

Website: introspectivemarketresearch.com

- polycaprolactone_polyol_market

- PCL_polyol_industry

- biodegradable_polyols

- sustainable_polyurethanes

- green_chemicals_market

- polyurethane_raw_materials

- eco-friendly_coatings

- automotive_polyurethane_market

- biomedical_polymers

- bio-based_polyols

- polycaprolactone_demand

- polymer_chemistry_market

- specialty_chemicals_industry

- flexible_foam_materials

- coating_elastomers_market

- adhesives_and_sealants_market

- construction_chemicals

- chemical_industry_trends

- PCL_market_forecast

- Introspective_Market_Research

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness