-

Nieuws Feed

- EXPLORE

-

Pagina

-

Blogs

-

Courses

-

Movies

Ink Resins Market: In-Depth Analysis & Market Share Focus

Introspective Market Research Forecasts Global Ink Resins Market to Grow at ~4.25% CAGR Through 2032, Driven by Eco-Friendly Inks and Packaging Boom

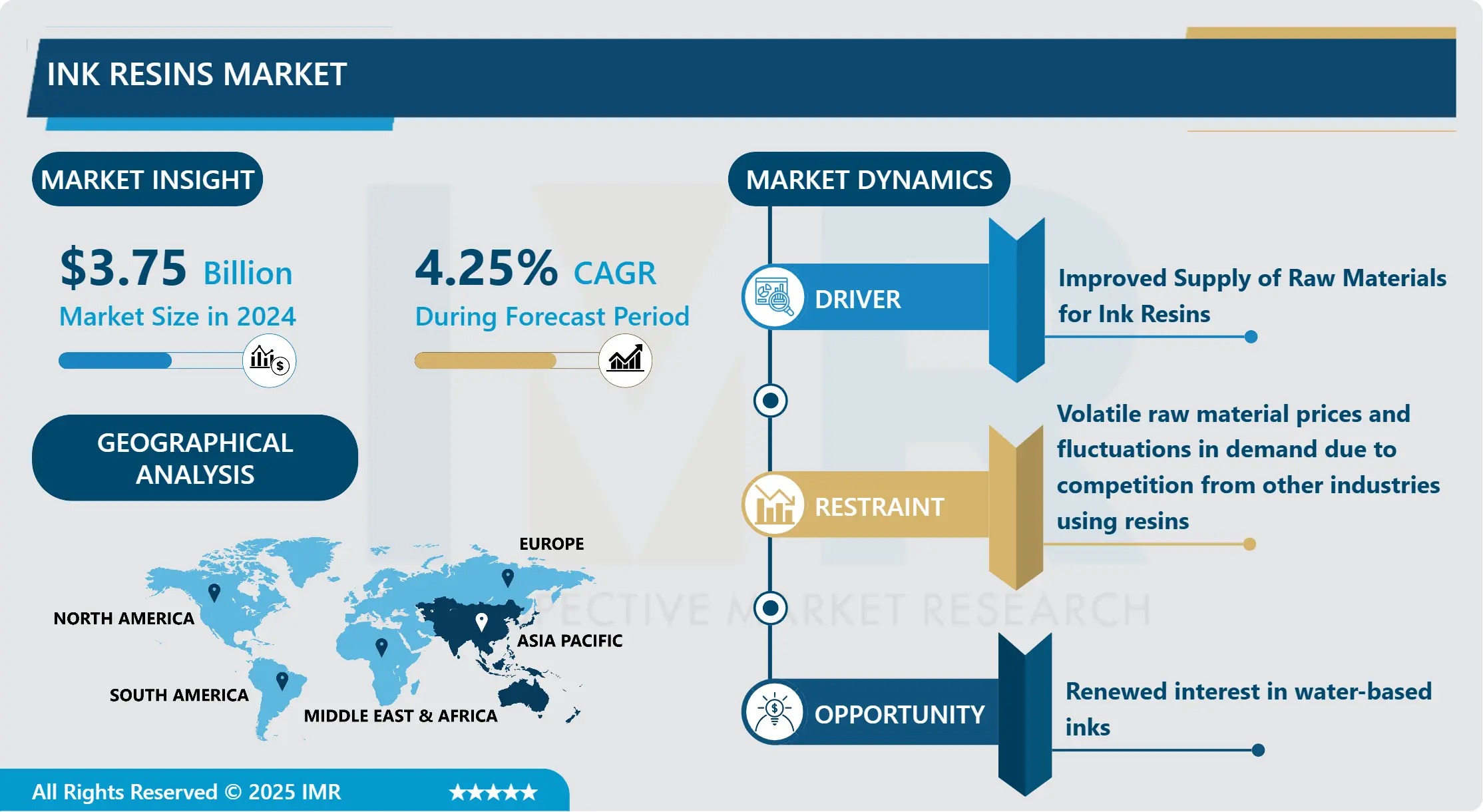

Introspective Market Research (IMR) today released its comprehensive analysis of the global ink resins market, projecting significant growth over the coming decade. According to IMR’s proprietary data, the market was valued at approximately USD 3.75 billion in 2024 and is expected to reach USD 5.45 billion by 2032, representing a compound annual growth rate (CAGR) of ~4.25% over the forecast period.

This expansion is being driven by a surge in demand for water-based and UV-curable inks, rising sustainability regulations, and strong growth in flexible packaging and digital printing. IMR’s report offers in-depth segmentation by resin type, technology, application, and geography, giving strategic insights for chemical manufacturers, ink formulators, and packaging players.

Quick Insights

-

2024 Market Size: USD 3.75 Billion

-

2032 Forecast Size: USD 5.45 Billion

-

Forecast CAGR (2024–2032): ~ 4.25%

-

Top Resin Types Covered: Modified Rosin, Hydrocarbon, Modified Cellulose

-

Major Technologies: Oil-based, Solvent-based, Water-based, UV-curable

-

Key Applications: Printing & Publication, Flexible Packaging, Corrugated Cardboards & Cartons

-

Leading Regions: Asia-Pacific (dominant), North America, Europe

-

Prominent Players: Kraton Chemical, Hydrite Chemical, Lawter B.V., The Dow Chemical Company, Sun Chemical, Huntsman, Emerald Performance, Celanese, Wacker, BASF, Evonik, Covestro, IGM Resins, DSM, among others.

What’s Fueling the Market?

IMR’s research identifies several critical drivers behind the ink resins market growth:

-

Sustainability Push: The shift toward water-based and UV-curable inks is accelerating due to heightened environmental regulations and demand for low-VOC (volatile organic compound) formulations.

-

Packaging Boom: Flexible packaging is growing rapidly, especially in Asia-Pacific, creating a strong demand for high-performance resin binders that deliver durability, adhesion, and print quality.

-

Digital Printing Adoption: The rise of digital printing, particularly in variable-data labels and on-demand packaging, is pushing formulators to develop resins compatible with inkjet and UV-curable systems.

-

Raw Material Improvements: Better availability and improved supply chain reliability for key resin raw materials are enabling resin producers to scale.

-

Innovation in Resin Chemistry: R&D into modified rosins, bio-based resins, and more efficient chemistries is opening new performance frontiers.

What Opportunities and Trends Are Emerging?

Could eco-resins become the default standard for high-performance inks?

As regulatory frameworks tighten and sustainability becomes a core consideration for both brand owners and ink formulators, water-based and bio-derived resin technologies present a strong growth lever. These resins not only help reduce environmental impact but also meet the functional performance demands of modern printing applications.

Is digital and UV-curable printing set to redefine resin formulations?

The adoption of digital printing and UV-curable inks is gaining momentum, particularly in e-commerce packaging, labels, and specialty graphics. This opens up opportunities for resin manufacturers to develop highly tailored binders that deliver instant curing, variable data performance, and long-term stability.

Expert Commentary

“Ink resins are no longer just a functional component — they’re becoming a sustainability and performance differentiator,” said Dr. Ananya Sharma, Principal Consultant at Introspective Market Research. “Manufacturers that can innovate in bio-based chemistries, reduce emissions, and deliver resins optimized for both traditional and digital ink platforms will lead the next wave of growth. Particularly in Asia-Pacific, where packaging demand is exploding, there is a huge opportunity for high-quality, low-environmental-impact resins.”

Regional & Segment Analysis

-

Asia-Pacific is projected to dominate market growth. Rapid industrialization in China and India, growing packaging sectors, and increasing adoption of modern printing inks are major catalysts.

-

North America remains an important market due to established printing infrastructure, high adoption of specialty inks, and strong R&D capabilities.

-

Europe continues to provide steady demand, particularly in eco-friendly ink chemistries and stringent regulatory environments pushing greener formulations.

By Resin Type:

-

Modified Rosins are widely used for their adhesion and compatibility.

-

Hydrocarbon resins and modified cellulose resins are important for specific ink performance needs, especially in UV and water-based formulations.

By Technology:

-

Water-based resins are rising fast due to sustainability benefits.

-

UV-curable resins are increasingly used for high-speed industrial and digital printing where fast curing is essential.

-

Traditional oil- and solvent-based technologies continue to be relevant for legacy printing processes and certain packaging inks.

By Application:

-

Flexible Packaging is a key growth vertical, leveraging resins that support high adhesion, durability, and print quality.

-

Printing & Publication remains significant, particularly in areas that require high-performance, stable inks.

-

Corrugated Cardboards & Cartons use resins in printing processes to ensure durability and cost-effectiveness for bulk packaging.

Recent Breakthroughs from Key Players

-

BASF and Evonik have been investing in bio-based and low-VOC resin lines, targeting environmentally conscious formulators.

-

The Dow Chemical Company has developed advanced UV-curable resins optimized for high-speed digital printing.

-

Lawter B.V. and Kraton Chemical are innovating in high-performance modified rosin resins, improving adhesion and stability in flexible packaging inks.

Cost Pressures & How to Make It More Efficient

Despite strong growth prospects, the ink resins market faces cost challenges:

-

Raw Material Volatility: Fluctuations in the price of base chemicals (resin precursors) can squeeze margins. IMR suggests long-term supply agreements and vertical integration as mitigation.

-

Energy Costs: Production of high-purity resins (especially UV-curable) is energy-intensive. Efficiency gains in production lines and investments in renewable energy can help.

-

Regulatory Compliance: Developing low-VOC or bio-based resins often incurs higher R&D costs. Companies can spread out these costs by targeting high-volume applications (like packaging) and premium segments (digital printing).

-

Process Optimization: Scaling production, optimizing batch processes, and reducing waste can lower per-unit costs.

-

Sustainability Premium: Resin manufacturers that align with sustainability trends can command premium pricing, provided they demonstrate value through lifecycle assessments and environmental benefits.

Why This Matters

Ink resins are at the heart of modern printing — they provide the backbone that enables adhesion, color vibrancy, durability, and environmental compliance. As the packaging, e-commerce, and digital printing industries continue to scale, the demand for innovative, sustainable, and high-performance resins is only going to intensify.

With environmental regulations tightening and sustainability becoming a competitive differentiator, resin-makers who can deliver greener, more efficient solutions will not only drive revenue but help reshape the future of printing chemistry.

Download & Connect

To explore the full Ink Resins Market Report — including detailed market forecasts, competitive heat-maps, opportunity matrices, and innovation roadmaps — you can Download Sample

To request a demo or speak with one of our Principal Consultants, please contact us at info@introspectivemarketresearch.com.

About Introspective Market Research

Introspective Market Research (IMR) is a leading global market intelligence firm specializing in advanced materials, specialty chemicals, life sciences, and high-growth tech sectors. Our in-depth research, quantitative forecasting, and strategic consulting help companies navigate emerging trends, assess innovation opportunities, and execute growth strategies.

Contact:

Introspective Market Research

Phone: +91-91753-37569

Email: info@introspectivemarketresearch.com

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness