-

Noticias Feed

- EXPLORE

-

Páginas

-

Blogs

-

Courses

-

Películas

UV Cured Acrylic Foam Tapes Market - Latest Advancement And Industry Analysis

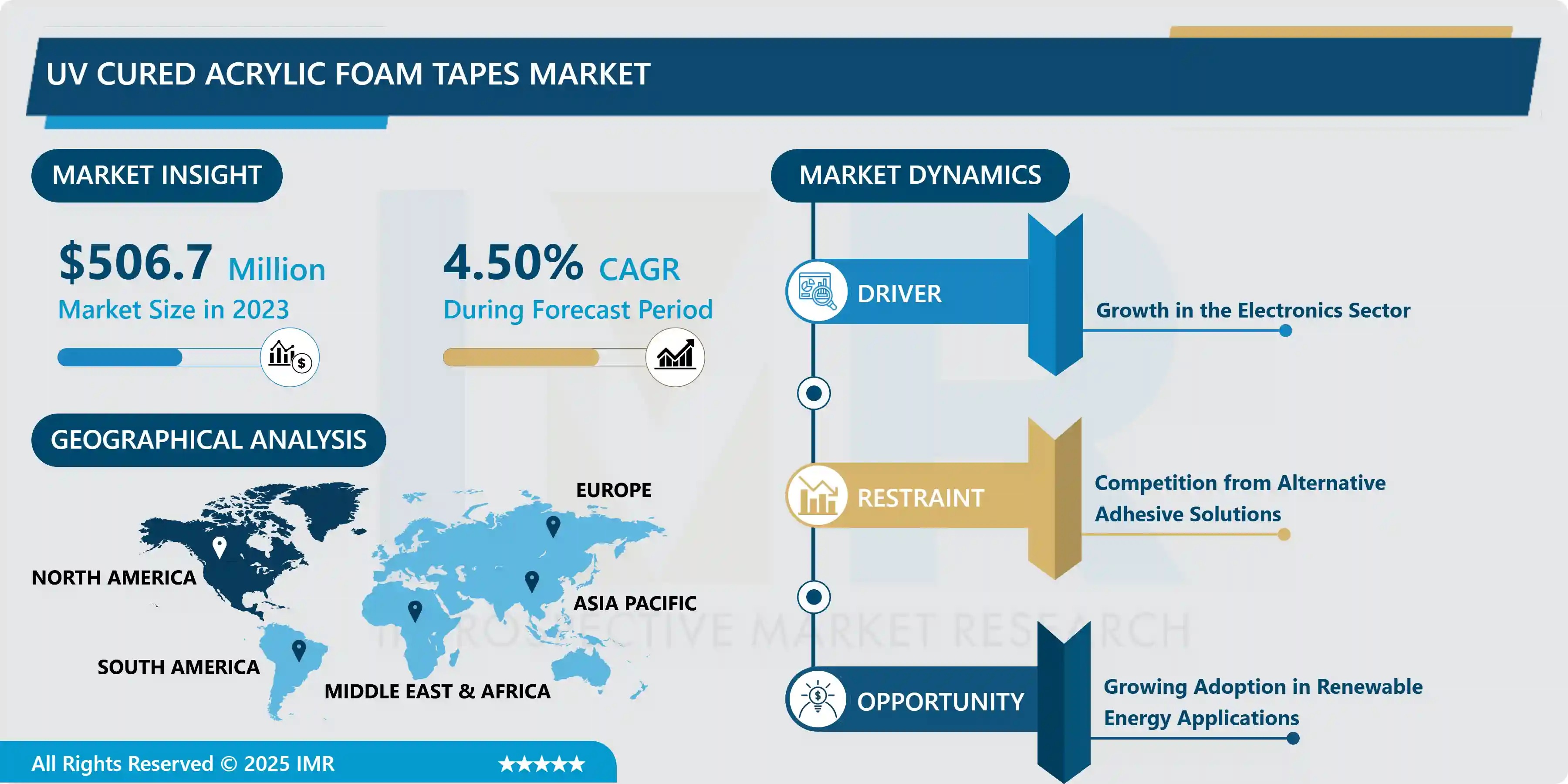

Introspective Market Research, a principal provider of chemical and advanced materials intelligence, today released its detailed study on the Global UV Cured Acrylic Foam Tapes Market. The analysis reveals that the market, valued at USD 506.70 Million in 2023, is poised for solid expansion, projected to reach USD 719.73 Million by 2032. This robust growth is supported by a stable Compound Annual Growth Rate (CAGR) of 4.5% over the forecast period of 2024–2032.

The UV Cured Acrylic Foam Tapes Market is rapidly being defined by the pursuit of high-performance assembly across critical industrial verticals. Its core growth is fueled by the accelerating shift to lightweight, durable materials in the automotive and aerospace industries, seeking to replace traditional mechanical fasteners. This expansion is further propelled by the surging demand from the Electronics Sector for advanced bonding solutions in miniaturized components, requiring the high durability and precise application afforded by UV curing technology. The solvent-free, low-VOC nature of these tapes also strongly aligns with stringent global environmental standards, solidifying their competitive advantage.

Quick Insights: The Advanced Bonding Market at a Glance

· Market Valuation (2023): USD 506.70 Million.

· Projected Market Value (2032): USD 719.73 Million.

· Steady CAGR: 4.5% (2024–2032).

· Dominant Product Type: Double-Sided Tapes, favored for high-strength, multi-substrate structural bonding.

· Leading End-User: Automotive Industry, driven by the structural and aesthetic requirements of vehicle assembly.

· Leading Regional Market: North America, expected to dominate the forecast period due to stringent standards and technological development.

· Key Driver: Growth in the Electronics Sector and global lightweighting initiatives.

· Core Opportunity: Growing Adoption in Renewable Energy Applications and medical device manufacturing.

High-Performance Adhesives: Market Revenue Projection

The steady growth forecast reflects the increasing industrial reliance on advanced, reliable bonding solutions that optimize both production speed and product durability, ensuring the market's value continues to climb toward the three-quarter billion dollar mark.

|

Metric |

Base Year (2023) |

Forecast Year (2032) |

CAGR (2024-2032) |

|

Market Value (USD Million) |

506.70 |

719.73 |

4.5% |

How is Advanced Curing Technology Overcoming Cost Pressures?

The primary challenge and cost pressure in this market arise from competition from alternative adhesive solutions (cheaper conventional tapes/liquid adhesives) and the high initial capital investment required for specialized UV curing equipment and stringent parameter control on assembly lines.

Manufacturers are strategically mitigating these costs and generating long-term benefits through technological advancements:

1. Process Efficiency (Cost-Efficient): The major breakthrough of UV curing is the ultra-rapid curing time—achieved in seconds compared to minutes for thermal-cured systems. This speed dramatically increases production throughput and enables in-line quality assurance, minimizing floor space and labor costs, which translates to a highly cost-efficient total manufacturing cost per unit.

2. Technological Breakthroughs & Cost Reduction: The shift toward UV-LED curing systems is a significant breakthrough. LED systems are highly energy-efficient (consuming up to 70% less power than mercury lamps) and generate less heat, which reduces operational costs and expands tape use into heat-sensitive electronics assembly.

3. Performance and Sustainability (Benefit): The resulting tapes offer superior durability, vibration dampening, and resistance to environmental factors. Furthermore, being solvent-free and having low VOC emissions provides a critical benefit by ensuring compliance with strict environmental regulations and contributing to a cleaner manufacturing environment.

Expert Insight on the Advanced Materials Shift:

"The UV Cured Acrylic Foam Tapes Market is moving beyond simple adhesion; it’s about providing structural integrity and long-term performance without the environmental cost of traditional methods," states Mr. Arthur Vance, Principal Consultant at Introspective Market Research. "While the market must always navigate cost pressures from conventional alternatives, the value proposition of UV-cured tapes—especially those tailored for EV battery management or high-stress solar panel assembly—is unmatched. The latest breakthroughs in bio-based acrylic formulations and next-generation UV-LED curing technology are not just improving tape performance; they are making the entire production process faster, cleaner, and ultimately, more cost-efficient for high-volume, high-value manufacturing."

Regional & Segmentation Analysis: Strategic Demand Points

Regional Leadership:

· North America is positioned to dominate the market over the forecast period. This leadership is sustained by the region’s strong focus on R&D, stringent manufacturing and quality standards, and massive ongoing investments in advanced manufacturing, particularly in the domestic Aerospace, EV, and specialized Electronics sectors.

· Asia-Pacific continues to be a major revenue engine due to its scale in general electronics and automotive manufacturing. However, North America is pushing the envelope for premium, high-performance UV-cured tape applications.

Segmentation Highlights:

· By Type, Double-Sided Tapes are expected to dominate the market. Their superior adhesion capabilities and ability to provide structural strength across multiple substrates—such as metal, plastic, and glass—make them indispensable in high-demand automotive and construction applications.

· By End-User, the Automotive segment holds the largest revenue share. This is driven by the industry’s perpetual need to reduce vehicle weight to meet fuel efficiency standards (and extend EV range), using tapes for exterior trim, panel bonding, and critical battery pack insulation.

· By End-User, the Electronics segment is a powerful growth driver, with UV-cured tapes used for bonding delicate screens, sensors, and internal components in increasingly compact and durable devices.

Industry Leaders Driving Innovation

Key players driving innovation and market share include 3M Company, Nitto Denko Corporation, Avery Dennison Corporation, Henkel AG & Co. KGaA, tesa SE, and Compagnie de Saint-Gobain.

Strategic Developments and Latest Breakthroughs:

· Renewable Energy Focus: Companies are actively developing specialized UV-cured tapes for use in solar panel assembly, offering weather resistance, structural adhesion, and longevity required for long-term outdoor exposure—a crucial emerging opportunity.

· Solvent-Free & Bio-Based Chemistry: Leaders are achieving significant breakthroughs in synthesizing solvent-free and bio-based acrylic formulations that reduce the industry's carbon footprint while maintaining or exceeding the performance metrics of traditional, petrochemical-based tapes.

About Introspective Market Research

Introspective Market Research is a premier global market research and strategic consulting firm specializing in advanced materials, chemicals, and manufacturing sectors. We deliver specialized, data-rich analysis to help global corporations, investors, and innovators anticipate market trends and optimize their strategic positioning in high-growth, high-tech environments.

Advance Your Bonding Strategy Today

Access the full report for in-depth regional capacity analysis, key competitor strategies, and long-term forecasts for the UV Cured Acrylic Foam Tapes Market.

[Download Sample Report: Introspective Market Research]

Contact Information:

Introspective Market Research

South King Drive, Chicago, IL

Phone: +91-91753-37569

Email: sales@introspectivemarketresearch.com

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness