-

Nieuws Feed

- EXPLORE

-

Pagina

-

Blogs

-

Courses

-

Movies

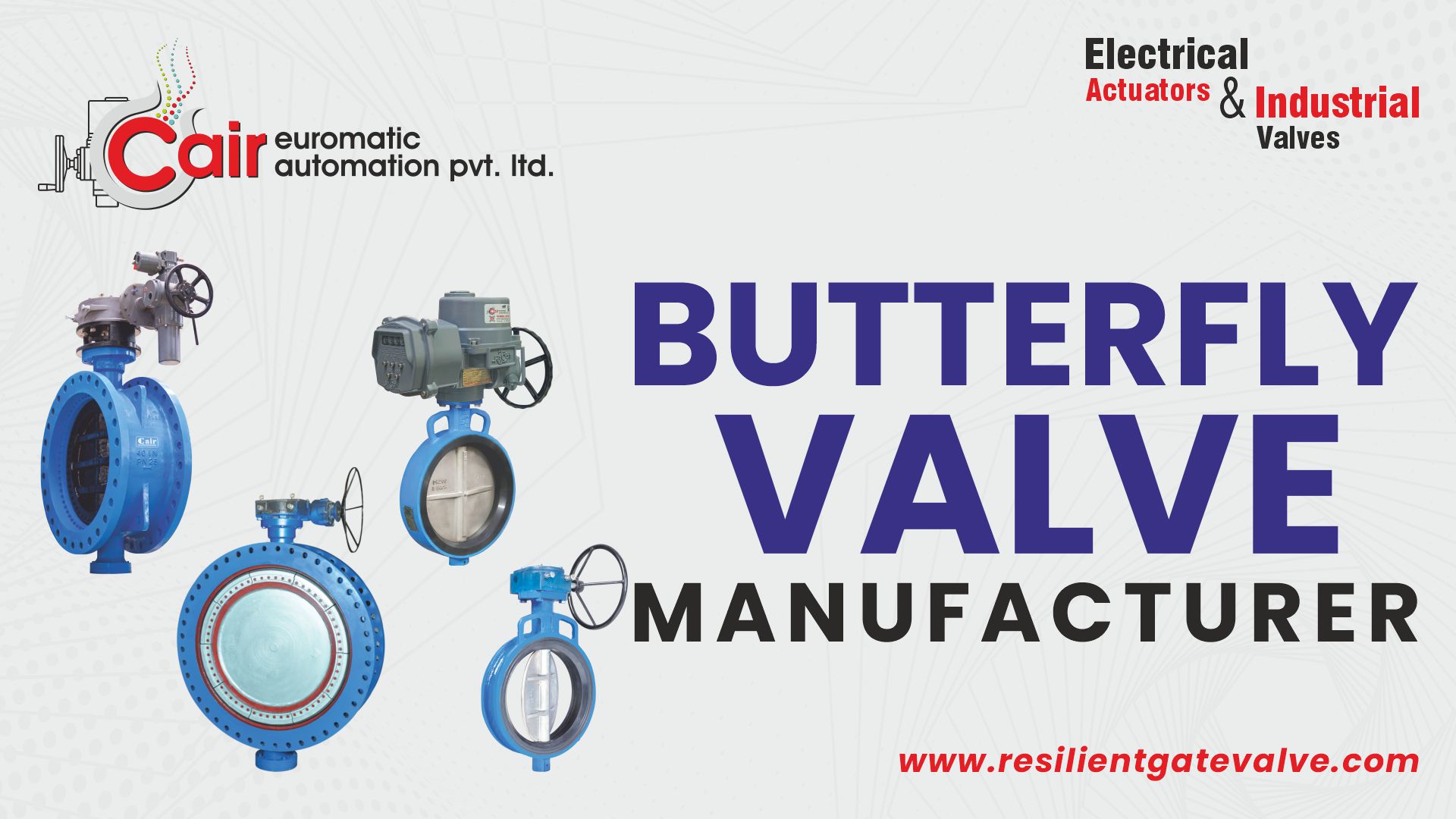

Why Butterfly Valves Are Ideal for Modern Flow Control Systems

In today’s industries, efficient flow control plays a critical role in ensuring smooth operations. From water supply systems to power plants and chemical industries, choosing the right valve is essential for reliability, cost-effectiveness, and durability. Among various valve types available in the market, butterfly valves have become a preferred choice due to their compact design, easy operation, and versatility.

Unlike traditional bulky valves, butterfly valves are lightweight, simple to install, and require minimal maintenance. This makes them a smart choice for modern flow control systems where space, cost, and efficiency matter.

What is a Butterfly Valve?

A butterfly valve is a quarter-turn rotational valve that regulates the flow of fluids through a pipeline. It consists of a disc mounted on a rotating shaft, which turns 90 degrees to open or close the flow. When the disc is parallel to the flow, the valve is fully open, and when it’s perpendicular, the valve is fully closed.

This simple yet effective mechanism makes butterfly valves fast and reliable in managing water, air, steam, and even corrosive chemicals.

Advantages of Butterfly Valves in Flow Control

1. Compact and Lightweight Design

Butterfly valves are much lighter than gate valves or globe valves. Their compact structure reduces installation space and costs, making them ideal for modern industries where efficiency is a priority.

2. Quick Operation

With just a quarter turn (90° rotation), the valve can fully open or close. This quick action not only saves time but also enhances system safety in case of emergencies.

3. Cost-Effective Solution

Compared to other large valves, butterfly valves are economical to purchase, install, and maintain. Their simple design means fewer parts, which reduces the chance of breakdowns.

4. Wide Range of Applications

Butterfly valves can handle different types of fluids—clean water, wastewater, oil, gas, and chemicals. This makes them versatile and suitable across industries like water treatment, HVAC, power generation, and food processing.

5. Durability and Long Life

Modern butterfly valves are designed with high-quality materials that resist corrosion and wear. This ensures longer life and reduced maintenance requirements.

Types of Butterfly Valves

-

Wafer Type Butterfly Valve – Most common, lightweight, and suitable for tight spaces.

-

Double Flanged Butterfly Valve – Offers extra strength and is widely used in large pipelines.

-

Lug Type Butterfly Valve – Provides strong pipeline connections and is easy to remove.

Each type is designed to meet specific industry needs, giving engineers flexibility in choosing the right solution.

Why Modern Industries Prefer Butterfly Valves

-

Space Saving: Compact design fits easily into modern, space-restricted plants.

-

Energy Efficient: Low-pressure drop across the valve ensures efficient flow.

-

Minimal Maintenance: Simple design reduces downtime and repair costs.

-

Versatile Use: Works in both small pipelines and large industrial systems.

For industries moving toward automation, butterfly valves can also be fitted with actuators for remote operation, making them suitable for advanced flow control systems.

Conclusion

In today’s fast-paced industrial world, companies are seeking solutions that combine efficiency, cost-effectiveness, and durability. Butterfly valves tick all these boxes, which is why they are increasingly used in modern flow control systems.

Whether in water supply, wastewater management, power generation, or chemical processing, butterfly valves offer compact, reliable, and long-lasting solutions. For businesses aiming to improve efficiency while reducing costs, butterfly valves are the smart choice.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness