-

Feed de notícias

- EXPLORAR

-

Páginas

-

Blogs

-

Courses

-

Filmes

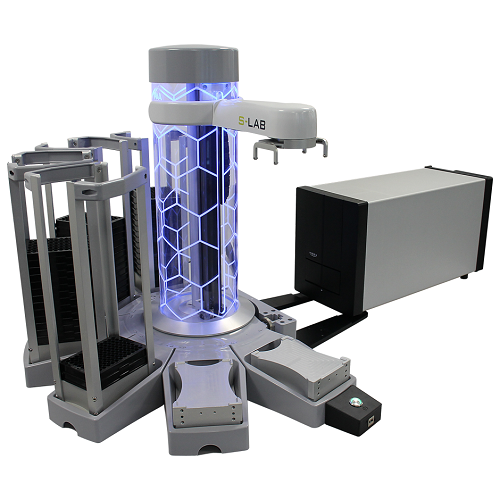

A Future-Forward and Intelligent Automated Plate Handlers Market Prediction

The prevailing Automated Plate Handlers Market prediction is one of a profound evolution towards smarter, more flexible, and more collaborative systems, moving far beyond the current paradigm of simple, pre-programmed "pick-and-place" robotics. The future of laboratory automation is not just about moving plates faster; it is about creating intelligent, adaptive, and interconnected ecosystems that can manage the dynamic and often unpredictable nature of scientific research. The next generation of automated plate handlers will be more than just logistical devices; they will be intelligent nodes in a larger "Lab of the Future" network. They will be equipped with advanced sensors and artificial intelligence, enabling them to make real-time decisions, optimize workflows on the fly, and work more seamlessly with their human counterparts, heralding a new era of human-robot collaboration in the laboratory.

The primary engine of this transformation will be the deep and pervasive integration of artificial intelligence (AI), machine learning (ML), and advanced sensor technologies. Future plate handlers will be equipped with machine vision systems that can not only read barcodes but also visually inspect plates to confirm the presence of a lid, detect spills, or identify an incorrect plate type, preventing costly errors before they happen. AI-powered scheduling software will move beyond simple, linear timelines to dynamic optimization. It will be able to analyze the status of all connected instruments, prioritize urgent samples, and intelligently re-route a workflow if a particular instrument goes offline, maximizing efficiency and uptime. Machine learning algorithms may also be used to predict when a handler's mechanical components are likely to require maintenance, enabling a shift from reactive to proactive service, which is a critical feature.

Looking further ahead, a major architectural shift will be the rise of collaborative robots, or "cobots," in the laboratory. Unlike traditional industrial robots that must be enclosed in large safety cages, cobots are designed with advanced sensors that allow them to operate safely in close proximity to human scientists. This trend will lead to the development of smaller, more mobile plate handlers that can be easily deployed and redeployed to different workstations as needs change. A scientist could simply wheel a cobot-based handler up to a new instrument, quickly teach it the required positions, and have an automated workflow up and running in a matter of minutes, not days. This will provide an unprecedented level of flexibility, making automation accessible for shorter, more varied experimental runs and breaking down the rigid distinction between manual and fully automated work areas in the lab.

Ultimately, the long-term prediction for the market is the seamless integration of plate handlers into a fully connected, data-driven laboratory ecosystem, often powered by the Internet of Things (IoT). In this "Lab of the Future," every instrument, robot, and sample will be part of a single, unified digital network. The automated plate handler will act as a central data hub, not only moving the physical plates but also automatically communicating with the Laboratory Information Management System (LIMS). Every time a plate is moved, its location and the timestamp will be instantly logged, creating a complete and flawless digital audit trail of the entire experimental process. This will provide an unprecedented level of data integrity, which is essential for regulated environments, and will enable more powerful, holistic analysis of experimental data, as the physical workflow and the digital data will be perfectly synchronized.

Explore Our Latest Trending Reports:

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness