-

Feed de notícias

- EXPLORAR

-

Páginas

-

Blogs

-

Courses

-

Filmes

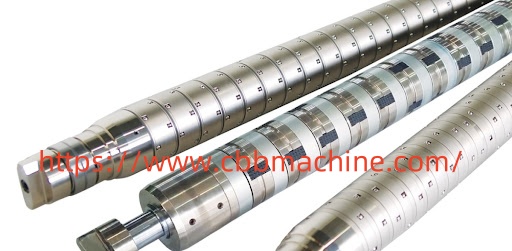

Cbbmachine Differential Air Shaft Design Enhances Safety And Operational Stability

In modern industrial processes, a well-designed Differential Air Shaft ensures consistent material tension, precise roll alignment, and smooth operation across various production lines. These devices are critical in sectors such as printing, packaging, textiles, and film converting, where even slight deviations in tension can lead to waste, defects, or equipment damage.

One of the primary benefits of this technology is its ability to accommodate rolls of varying diameters without manual adjustment. By automatically balancing tension across the roll width, operators can maintain smooth unwinding or rewinding, preventing wrinkling, stretching, or misalignment. This capability significantly reduces production errors and improves overall efficiency.

Durability and reliability are also crucial. High-quality materials and precision engineering allow the shaft to withstand prolonged operation in demanding environments. This robustness minimizes maintenance requirements and production downtime, ensuring that manufacturing lines run efficiently and continuously.

Operational efficiency is further enhanced by automation compatibility. Advanced designs can interface with PLC systems or other control units, providing real-time monitoring and predictive adjustments. This integration allows manufacturers to maintain optimal tension, improve product consistency, and reduce operator intervention, which is especially important for high-speed production lines.

Safety is another significant advantage. Proper tension control reduces the risk of material slippage, roll collapse, or mechanical failure, protecting both operators and equipment. By ensuring consistent handling of materials, manufacturers also prevent costly damage to sensitive products, preserving quality standards across multiple production runs.

Flexibility is a key feature of modern designs. A single unit can manage a wide range of material types and widths, making it a versatile solution for facilities producing multiple product lines. This adaptability supports lean manufacturing strategies and reduces the need for separate equipment for different processes.

Sustainability and cost efficiency are additional benefits. By minimizing material waste, rework, and energy consumption, this solution contributes to environmentally responsible production. Consistent tension and alignment reduce defects, ensuring that resources are used efficiently and production costs remain controlled.

In conclusion, integrating a high-quality shaft that provides differential tension control is essential for precision, safety, and efficiency in modern manufacturing. Its ability to manage varying roll diameters, reduce downtime, and maintain product quality makes it indispensable for industrial operations seeking consistent and reliable performance.

For more information, visit https://www.cbbmachine.com/news/industry-news/differential-air-shafts-key-components-applications-benefits-and-more.html

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness