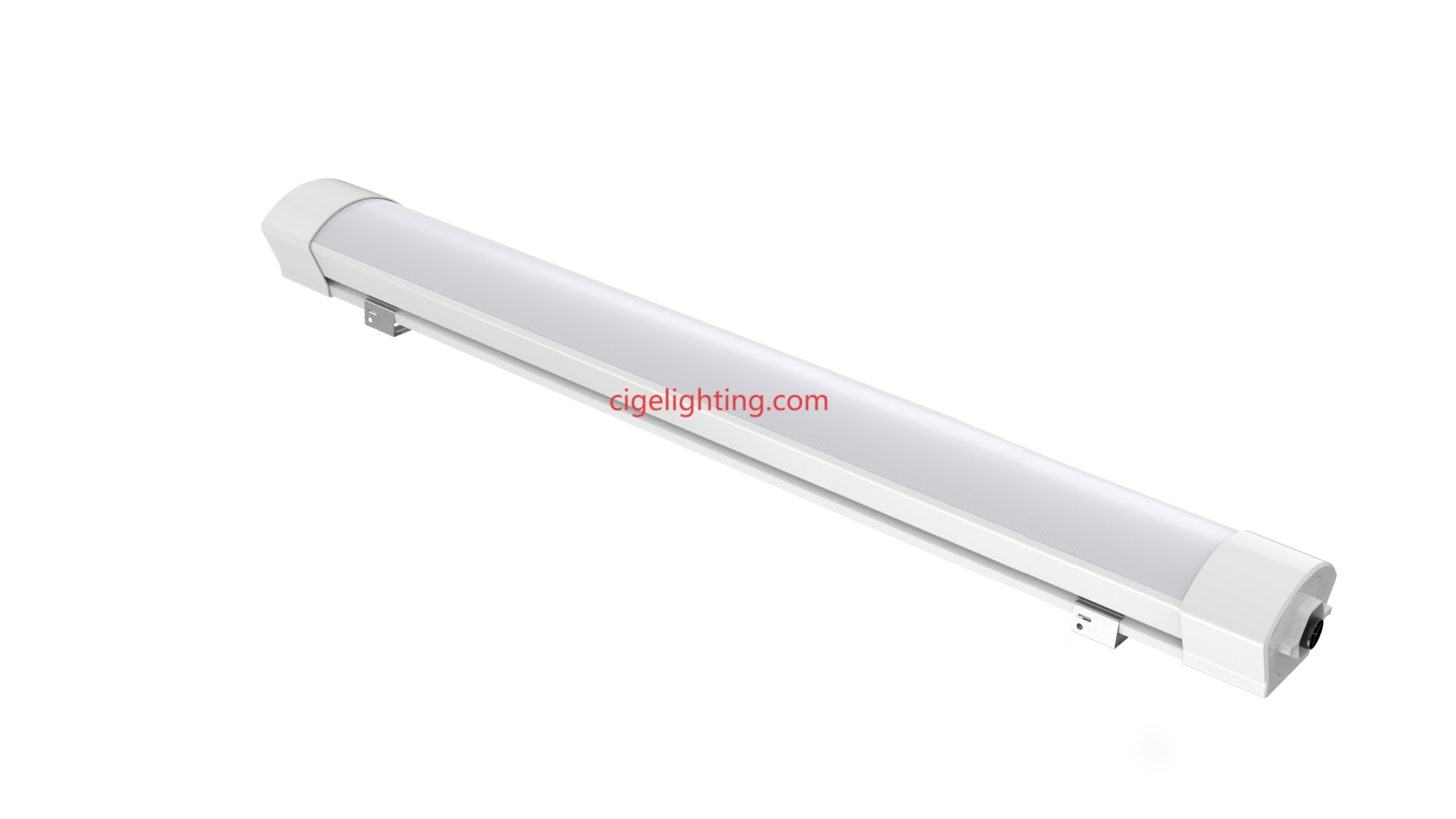

Verified Marine Integrity: Cige Triproof Light Factory

Harsh environment lighting faces critical performance challenges where superficial material claims often diverge from observable reality. Premature corrosion in aggressive settings reveals vulnerabilities in protective methodologies that rely on temporary barriers rather than intrinsic material immunity. Responsible Triproof Light Factory operations address this through molecular-level engineering that transforms environmental resistance into a core material property. They utilize alloy compositions where metallic elements form natural passive layers that self-regenerate when compromised. Polymer housings incorporate sacrificial molecular structures that absorb corrosive elements while maintaining structural integrity. This approach creates inherent immunity to salt, chemicals, and moisture at the material's foundation rather than depending on external coatings that degrade unpredictably. The methodology represents a fundamental shift from claimed protection to engineered resilience, ensuring luminaires maintain sealed integrity against environmental penetration throughout their operational lifespan.

Validation demands exceeding standardized testing paradigms. Ethical manufacturers implement multi-phase corrosion verification where samples endure accelerated salt exposure cycles followed by thermal stress and mechanical impact sequences. Crucially, post-testing evaluates both surface integrity and internal component protection through hermetic sealing checks. Responsible Triproof Light Factory facilities maintain coastal exposure testing stations where product batches withstand real-world marine conditions for extended durations. These installations provide continuous performance data that validates laboratory predictions against observable field performance. Transparent reporting of both controlled testing and real-world validation creates manufacturing ecosystems where environmental durability becomes demonstrably verifiable rather than theoretically projected. This comprehensive approach empowers specifiers to select solutions with confidence in challenging installations where failure carries significant consequences.

For critical environments demanding uncompromised protection, Cigelighting redefines corrosion resistance standards. Our Triproof Light Factory integrates molecular defense systems and subjects every product to multi-stage environmental validation. We maintain open-access coastal testing sites for independent verification. Collaborate for luminaires where protection is engineered, not claimed.Click https://www.cigelighting.com/product/ to reading more information.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness