-

أخر الأخبار

- استكشف

-

الصفحات

-

المدونات

-

Courses

-

الافلام

The Evolving Trends Shaping the Future of Predictive Maintenance

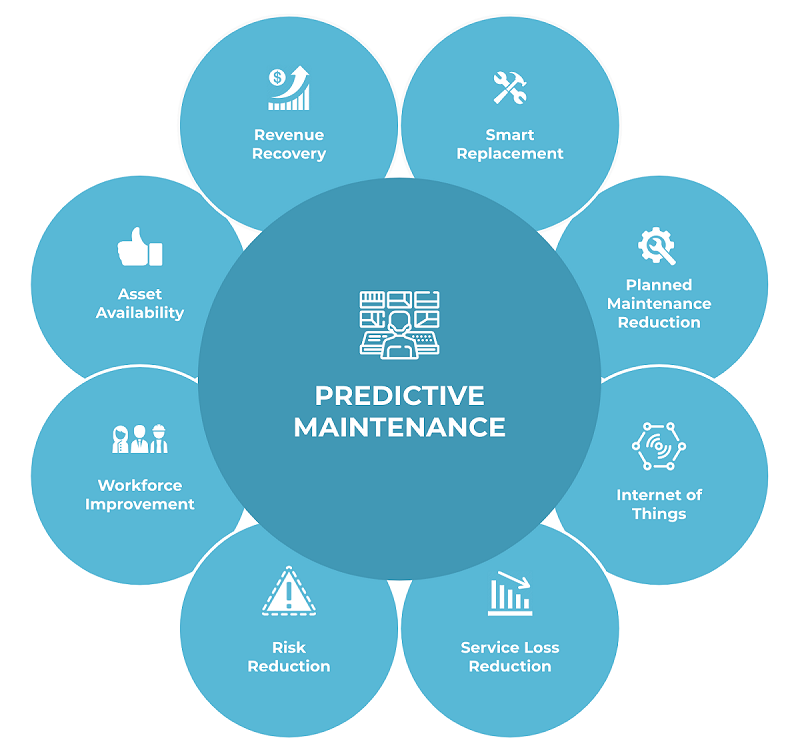

Observing the current landscape reveals several key Us Predictive Maintenance Market Trends that are pushing the technology into its next phase of evolution, focusing on greater intelligence, accessibility, and integration. One of the most significant trends is the strategic shift from cloud-centric processing to a hybrid model that incorporates edge computing. While the cloud remains essential for large-scale data storage and complex model training, there is a growing recognition of the need for real-time analytics directly at the machine level.

Edge computing involves deploying compact, powerful computing devices near the assets themselves to perform initial data processing and run predictive models locally. This approach dramatically reduces latency, which is critical for equipment that requires an immediate response to an anomaly. It also lowers data transmission costs by sending only relevant insights, rather than raw sensor streams, to the cloud. This trend towards intelligent edge devices is making predictive maintenance more responsive, resilient, and suitable for a wider range of high-speed industrial applications.

Another powerful trend reshaping the market is the democratization of AI through the development of low-code and no-code predictive maintenance platforms. Historically, implementing a PdM solution required a dedicated team of data scientists to clean data, select features, and build and validate complex machine learning models. This created a significant skills barrier for many organizations. In response, vendors are now developing highly intuitive platforms with graphical user interfaces and automated machine learning (AutoML) capabilities.

These platforms guide maintenance engineers and reliability specialists—who have deep domain expertise but may lack coding skills—through the process of building and deploying their own predictive models. This trend is a game-changer, as it empowers the people closest to the equipment to leverage advanced analytics, fostering a culture of data-driven decision-making on the factory floor and dramatically accelerating the adoption and scaling of PdM initiatives across the enterprise.

Finally, a crucial strategic trend is the increasing integration of predictive maintenance insights into broader business processes under the umbrella of Asset Performance Management (APM). Companies are moving beyond using PdM solely as a maintenance tool and are starting to leverage its data to inform a wider range of strategic decisions. For example, insights into which machine components fail most frequently can be fed back to engineering teams to improve future equipment designs. Data on asset health and reliability can be used by finance departments to create more accurate capital expenditure forecasts.

This holistic approach connects the health of physical assets directly to the financial health of the organization. This trend involves tighter integration between PdM platforms and enterprise systems like ERP, EAM, and PLM (Product Lifecycle Management), breaking down departmental silos and ensuring that asset intelligence is used to optimize performance across the entire value chain, solidifying PdM's role as a strategic enterprise asset.

Explore Our Latest Trending Reports:

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness